.

SAVIO INDIA LTD

Savio India is the manufacturing unit located in Coimbatore, Tamil Nadu. It was set up with an intention of providing the world class SAVIO products, specific to India�s textile market. In 2008, the unit started manufacturing Two-for-one twisters with Italian technology, for local and export market.

With its corporate office located at Coimbatore with a strength of about 200 people and sales offices also at Ludhiana and Kolhapur, the company is presently serving the whole territory of India, Nepal and Sri Lanka.

We are proud to be associated with Indian economy and buoyant textile industry since 1991. The success of Savio in India encouraged us to set up a full-fledged technical assistance team in Coimbatore and service centres across the country, to offer prompt and value added technical services to our customers in India. Today we are happy to be an integral part of Indian Textile Industry; our vision is continue to provide quality service to all our customers leveraging our global strengths".

Savio now operates worldwide in the production and marketing of automatic winders,two for one twisters tfo machine, tfo twisting machine tfo yarn machine and rotor spinning frames with manufacturing plants in Italy, China and India.

This evolution was accomplished in time by taking as a point of reference the research and development, a strong orientation to the maximum production flexibility and to maintain high quality standards.

This focus has resulted in a very strong driving force that led the company to realize an evolved production system to respond quickly to the demands of the textile industry worldwide, offering the market a wide range of increasingly advanced textile machines with excellent performances and high reliability.

Savio can count on a direct commercial presence in over 60 countries worldwide, on service and on-site maintenance, technical training and courses for customers' technicians. Global dimension, flexibility and manufacturing excellence are the main assets for a strategic leadership that will renew over time.

Savio is present since late 1950s in twisting technology, first with ring twisting machine FM280 in 1949, followed by the first two for one twister in 1963. With a wide range of Two-for-one twisters diversified for different market requirements, Savio twisting machines respond to the demands of customers looking for a significant reduction in labour and energy.

TWO FOR ONE TWISTER

TFO Machine � Sirius

Middle and Far East countries, that constitute the key Markets for Two for one Twisters and tfo machine, are today showing requirements that until now have characterized the �Traditional� western markets. The new needs are diverse, not only among each Market area, but also throughout a single Market.

The main requirement is to reduce workforce, which is becoming, day by day, more and more difficult to find, even if its costs are still strongly competitive if compared with the western markets. Moreover, apart from the need to reduce the initial investment costs as well as power consumption, a great number of Companies keep asking for products which can grant low maintenance times and costs. To meet those new requests, sometimes in contradiction one with each other, Savio has developed its brand new Two for One Twisters generation, Sirius, that is able to solve all the problems mentioned above.

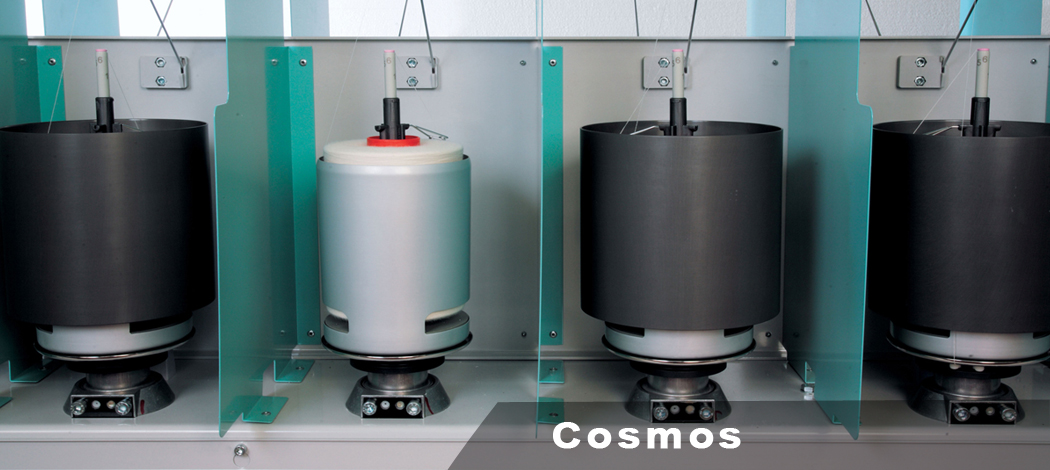

TFO Machine� Cosmos

Cosmos represents another Savio proposal in the field of Two-for-one twisting, tfo machine twisting to ensure maximum cost effectiveness of the technological process through constructional solutions that allow a reduction in investment with a minimum of energy consumption.

The aim of all this is to maximize the productivity of the machine, the quality of the package and the twisted yarn, along with the technological flexibility, that is today an indispensable requirement for any textile market.

TWO FOR ONE TWISTER SERVICES

Coimbatore showroom displays a wide variety of tfo, two for one twister machines, locally made by Savio India and imported by Savio Italy. Indian customers can take advantage to check, make trials and be attended for dedicated training courses.

With a team of 80 experienced and competent service engineers, Savio India is well equipped to address all the service needs for customers at shortest possible time frame. Technical assistance, rapid detection of problems, trouble shooting and improving performances are the leading features of our after sales service. At Coimbatore, an electronic lab, with a team of skilled engineers and sophisticated simulators, is also operative. Textile testing laboratory with other latest equipment are also a part of our service offered to our customers. Their needs in terms of testing the yarn quality, yarn strength and other physical parameters are addressed on time by a team of qualified technicians. A large spare parts store with both bonded and non-bonded warehousing facility is available. EOU/EPCG customers can get concessions on customs duty on imported spare parts against requisite customs documents.

TWO FOR ONE TWISTER TRAINING

Savio India has always considered the training of the customers� technicians as a very important aspect of the business. Periodical training classes are conducted at Coimbatore and Ludhiana offices.